Adventures in Plastic Casting v1.2

Written By: Juan G. aka “ArmJunkie”

Click Here To Download This Article in PDF Format.

- Alumilite’s Website (various supplies and kits): www.alumilite.com

- Tap Plastics’ Website (supplies and video tutorials): www.tapplastics.com

Introduction

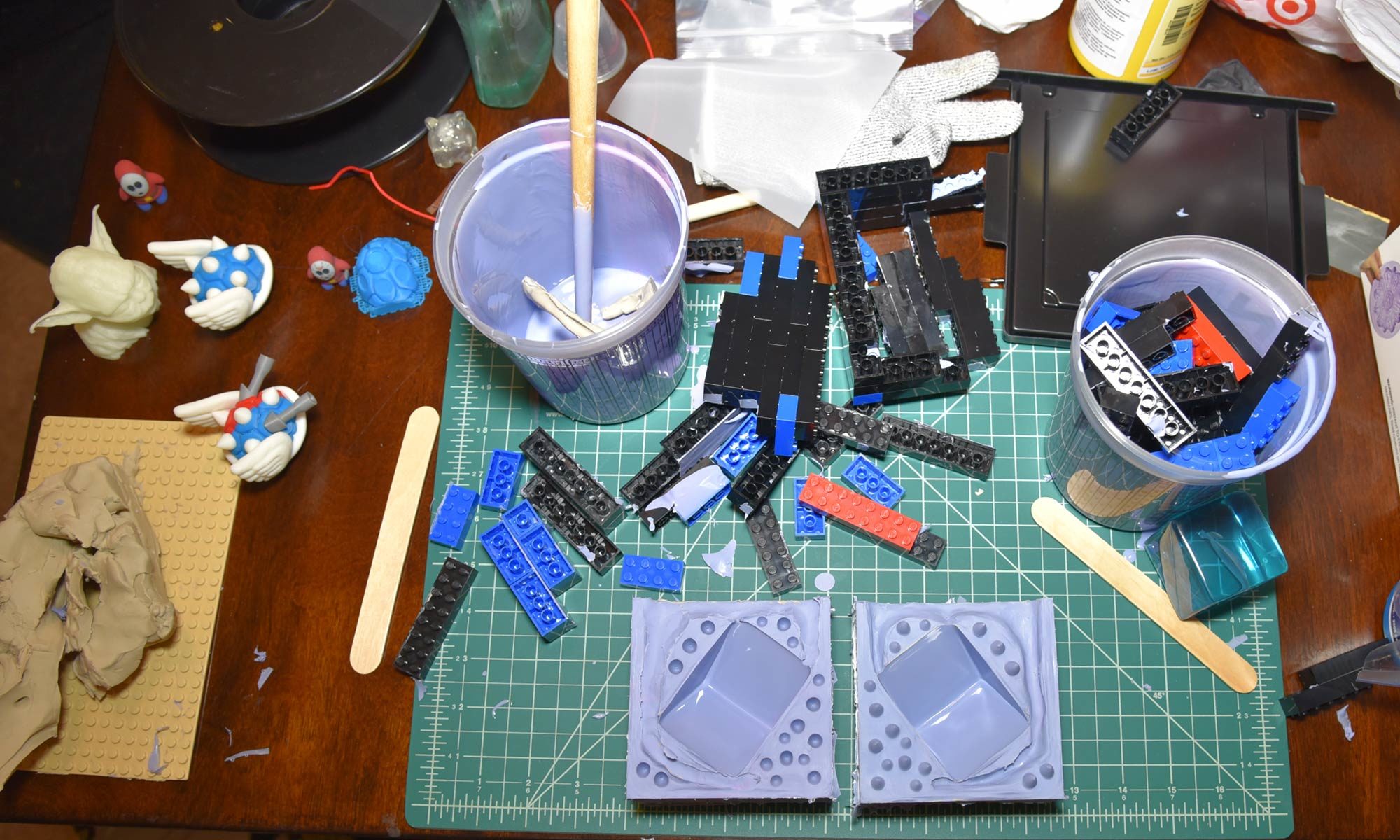

This article serves to chronicle my experiences in casting a plastic part using this Alumilite Mini Casting Kit. I learn more from my mistakes than my successes. This was especially the case when using this kit for the first time.

Depending on the vendor you can find this kit for around $30 USD. I figured the techniques and processes learned would help me out greatly in robotics and in future projects.

Now that I have some experience in this I can now justify buying the chemicals in bulk quantities. This is a great way to develop prototypes and test out ideas.

Box Art

Checking out the nice box art and kit information…

This kit is very cool stuff! The box art suggests this is a very versatile kit. Remember, this kit is more or less an introductory kit. If you wanted to do a large number of castings from a variety of molds you would be better off buying the chemicals and supplies individually and in bulk.

I now needed something to clone in plastic. Judging by the amount of silicone I had, the mold would have to be small. I decided to duplicate the robot head of my kid-brother’s toy that he unknowingly donated to my cause.

While the kit offers plenty of plastic resin chemicals, the kit only provides a small quantity of silicone for creating a mold. In essence you can create one small mold, and many plastic castings with this kit.

Supplies You Will Need

• Cardboard

• Hot Glue Gun

• Pencil with eraser end

• Pen Plastic casing

• Alumilite Mini Casting Kit (Provides silicone rubber, casting resin, clay, mixing cups, and stirring sticks!)

First you must isolate the piece you wish to duplicate in plastic. In my case, this robot head from a toy. The piece must have all openings sealed off. In the case of my piece the “eye” of my robot was a loosely fitted LED light. I have removed the LED piece within the robot head and filled the hole with the clay provided in the casting kit.

Build a Box

Construct a small box out of cardboard. I used the hot glue gun to attach the seams from the outside. Once built, you can then begin to squish the clay down in the base of the box. You want to create a thick, flat layer. Before placing the robot head in the box I attached a piece of the pen casing I had cut into the robot’s neck opening. This will serve as a pouring channel for the plastic resin. I securely attached the piece of pen casing to the robot’s neck using the hot glue gun. Now gently press the robot head into the clay. I pressed to the half-way mark of the piece. Next, press in and smooth the clay around the perimeter of the piece.

I suppose an alternative to this method is to pour the silicone rubber directly to the bottom of the cardboard box. However, I had no idea if the robot head would be supported by the viscosity of the silicone rubber. I figured the clay base was a sure bet. Maybe that will be another experiment for another time 🙂

The clay must be as smooth as possible. Take special care to cover up any exposed edges around the object. Press in the eraser end of the pencil into the clay a few times. This will dimple the clay, making two interlocking pieces.

Create Mold

I used a bit of clay around the corners of the box to ensure no leaks. I suspect I may have gotten an old box of casting materials because mixing the silicone and the catalyst was very difficult. It did not poor in easy which may have partially ruined the mold… more on that later.

This is a good time to mention that this is not the best method for creating a large silicone mold. For something like that you would “paint” on layer by layer a silicone “skin”. Of course, this means waiting for the silicone to partially set somewhat in-between layers. Once your silicone skin is created you must wait for it to completely dry and set. Then you would use either use plaster or fiberglass matting and epoxy to create a support structure for the skin. The skin retains the details and the support structure maintains the shape of the mold. This topic is beyond the scope of this guide, however. Research on the web for more details.

Once the silicone has hardened I removed the back of the cardboard mold. I carefully picked off the clay. Here is where I made my first huge mistake. I got overexcited and decided to remove the robot head to take a picture. This was a huge mistake because once dislodged, the piece would no longer fit snugly when placed back. This will produce a slightly warped piece and the “antenna” on the side will be completely ruined.

Oh well, let’s move on….

I reinsert the robot piece in its mold cavity. At this point you apply a very thin layer of Vaseline (petroleum jelly) or a release agent (if you have any on hand) to the silicone mold. This is to ensure that the two halves of silicone will not bond together.

My robot head has a smooth surface so I didn’t fear that the silicone would get stuck to it. If the texture of the object you are casting is rough or complex you may coat the piece with Vaseline or a release agent.

Now we go on to pour the second half of the silicone. The second half of the silicone will complete the mold and also create the “female” dimples that will assist in mold alignment and interlocking.

Once the second half of the silicone mold has hardened you can safely remove the robot head piece. You can extract both silicone halves from the cardboard holder.

You can clearly observe the color difference between the two silicone mold halves. This is more proof that my chemicals are old and that I failed to do proper, even mixing. The silicone chemical was not uniformly mixed. Pouring the second batch of silicone was even more difficult and took longer to dry and harden. It’s amazing that anything was cast at all.

All things considered, it’s a pretty good mold for a first timer. I can see that the mold won’t be perfect. I got some air bubbles trapped due to not having my own vacuum chamber. I can see a problem with the robot’s antenna. It must have moved during the mold making process. It doesn’t look like the antenna will cast properly but let’s continue anyway.

There is a way to mitigate trapping air bubbles if you don’t have access to a vacuum chamber. A vacuum chamber will remove any air bubbles trapped in your silicone that you may have introduced from mixing.

Several websites suggest using a small Dixie paper cup to hold the pre-mixed silicone before pouring. You puncture a small hole at the bottom of the cup. You allow the silicone to uniformly fall into a single location in the cardboard box. Use your best judgment to pick a place that will minimize trapping air bubbles. You may want to do this so that the cup drains out from the edge of a table while the cardboard box with the piece rests on the floor. You certainly don’t want to be holding the cup because this is a slow process. The silicone will pour as a single thin, continuous stream. Air bubbles automatically burst in this thin stream. Please make sure you don’t have any fans turned on or a breeze coming in from the window. This thin, continuous stream of silicone can easily be disturbed by air currents. This slow silicone “avalanche” will push out much of the air as it oozes down, up, and around your casting piece; minimizing trapped air in the silicone that will lead to mold errors.

Notice how dimpling one side in the clay produced the interlocking teeth. Other than the botched antenna there were no serious mold deformations. You can spot two small air bubbles on the left edge of the left mold half in the following image.

Here you can compare and contrast the robot head piece with the mold. A lot of detail is captured by the mold.

In this image, you can see the pour channel used for pouring the plastic resin into the mold cavity.

Prep for Plastic Resin Casting

Here’s a cool tip picked up from model making websites. To measure how much plastic resin to use we must find the volume of the mold. Rice works well for this. The more accurate your measure the more money you save… these chemicals are expensive!

Here the mold cavity is filled with rice. Pour out this rice into a measuring cup to find out the volume of the cavity. It’s a good idea to give yourself a nice buffer because a little over spilling is better than under filling.

Once you know the volume of the mold you can calculate how much plastic resin (chemical solution B) and activator (chemical solution A) to use following the correct ratio. The ratio is usually written on the bottles.

I’m going to need about 1/4 fluid ounce of A and B to cast this.

This is where I make another huge mistake. I decide that a bit of glue from a hot glue gun and some flimsy rubber bands are enough to hold the silicone mold together. What I failed to anticipate is that the plastic resin EXPANDS (and heats up) as it hardens. What I should have done is used two rigid boards and clamps to hold the mold together. The intent is not to squeeze the mold together (which can deform the casting) but to ensure that any expansion in the plastic resin is forced back out of the pour channel.

Let’s attempt a first casting…

I inspect the plastic resin chemicals (A and B solutions) and discover that part B seems to be really, really viscous. On closer inspection I can see particulates suspended unevenly in the liquid. I assume this is an old kit that has been sitting on a shelf for a rather long time. This is later confirmed when I repurchase the kit from a different vendor and the chemicals are in better condition.

[CASTING ATTEMPT #1]

I believe the unevenness of the chemicals contribute to my first failed pouring. The directions clearly state to mix equal parts of both A and B together for 25 seconds then pour. I follow the directions and the liquid gets extremely hot and hardens mid-POUR!!!! I was not happy.

Let’s inspect the failure….

Here you can see how quickly the plastic hardened. It took the shape of the pour. Aside from the failure, that is pretty impressive.

Judging from the partial cast of the head the plastic did its job. I’m just going to have to mix and pour faster.

Now it is time to remove the failed attempt and clean out the mold to try again.

The plastic is rock hard and very stiff. This is not the bendy, stretchy plastic I anticipated. This is something to note when using this kit on future projects.

One thing I noted was that the casting was really smooth. The texture is not bumpy or gritty at all. A little trimming and sanding is needed.

Another thing to mention is I still need to figure out the best way to color this plastic. Painting is the obvious option but experimenting with dyeing the chemicals before they set is another. This will be another experiment for another time. 🙂

Time to prepare for another pour attempt….

[CASTING ATTEMPT #2]

FAILURE AGAIN! This time I have the reverse problem. I mixed too fast and the chemicals didn’t mix well enough. The plastic never quite hardens and remains a syrupy mess.

This failed casting was the worst. It made my mold all sticky and extremely difficult to clean out. Let’s try this again…

[CASTING ATTEMPT #3]

This time the plastic mixing went perfect. Time was dead on. The problem? The resin expands before hardening. I failed to note this and the resin actually separated my mold while it was hardening. The cast looks fine from the front and back but the sides are all stretched out.

You can see the large thick trim around the side of the piece. This is where the mold halves were separated and filled in by the expanding plastic resin.

The mold did capture a lot of detail. Since I don’t have any clamps on hand, I’m going to tape up the mold securely and try again.

[CASTING ATTEMPT #4]

This is the best casting attempt yet. All that’s left is using an exact-o knife and some sand paper to clean up the excess plastic

Final Results and Inspection

With each casting I got better and better at this. I’m really proud at what I learned.

Here is the cleaned up final attempt. Not bad, eh?

Most of the major details were captured beautifully.

This is how the antenna came out due to the bad mold. I’m just going to cut it off and sand it. Other than that imperfection it was a good cast.

Light sanding, a little trimming or filling in, and some paint and we have a very close duplicate to the original.

Conclusion:

Besides the fact that the batch of chemicals I got was old, this kit was a great first introduction to plastic mold making. With the knowledge I learned and the experience gained I feel more confident moving toward higher quality casting materials.

One thing I noticed is that if I’m going to continue to mold my own parts out of plastic that I need to invest in a vacuum chamber. It’s the only way I will be able to get all the air bubbles out of the liquids before using them. I’m going to go scour our garage for an old bicycle air pump to convert into a vacuum pump.

…. Now all I need is a great invention to invent. As always, thanks for checking out this guide. Let me hear your feedback and experiences. Adios.

Email: webmaster ~_~_~ At ~_~_~ armjunkie.com